Enabling Tomorrow's Circular Chemistry:

Next-Generation Green Methanol Production

Using a microwave-generated cold plasma, Ionic Impact's innovative approach brings peak efficiency and flexibility,

enabling a robust and scalable production of green methanol and empowering a circular chemical industry

Ionic Impact is Advancing the Green Methanol Market

Our Technology

SIMPLE AND POWERFUL

Cold Plasma

...as the chemical reaction zone of your dreams

Biogas

...as a circular resource

Microwaves

...for efficient and flexible plasma ignition

Precision

...resulting in high methanol yields

Modularity

...ensuring a globally available, decentralized PtX-solution

Efficiency

...enabling a smooth transition into the circular economy

Green Methanol - Fuel of the Future?

Green methanol has emerged as a frontrunner in the quest for sustainable and environmentally friendly alternative fuels in the shipping industry. Derived from renewable sources such as biomass, industrial waste, or captured carbon dioxide, green methanol offers a compelling solution to reduce the maritime sector's carbon footprint. As a clean-burning fuel, it produces significantly fewer emissions compared to traditional marine fuels, contributing to improved air quality and mitigating climate change. Its compatibility with existing infrastructure and engines makes the transition to green methanol relatively seamless for the shipping industry. With its potential to drive decarbonization efforts and meet stringent environmental regulations, green methanol stands out as a promising and efficient alternative fuel, paving the way for a more sustainable future in maritime transportation.

Towards a Circular Chemistry

Beyond its role as a sustainable shipping fuel, green methanol exhibits versatility in various applications, contributing to the broader transition towards a low-carbon economy. One notable application is in the realm of power generation, where green methanol can serve as a reliable and cleaner alternative to traditional fossil fuels, helping to reduce greenhouse gas emissions. Additionally, it has found utility as a feedstock in the chemical industry, serving as a building block for the production of various chemicals and materials. The automotive sector is also exploring green methanol as a potential fuel for internal combustion engines or fuel cells. Moreover, its potential as an energy carrier for storage and transportation in sectors like aviation and heavy industry further underscores its significance in the pursuit of sustainable energy solutions. Green methanol's adaptability across diverse sectors highlights its promising role in driving the transition towards a more sustainable and eco-friendly energy landscape.

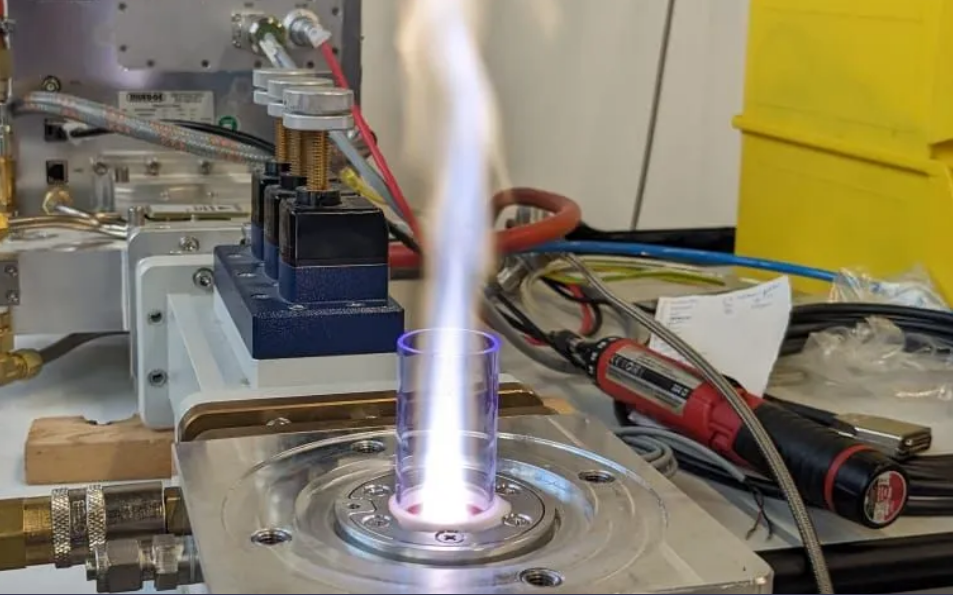

Microwave-Generated Cold Plasma as the Key to Efficiency

Microwave-generated plasma has emerged as a highly favorable reaction zone for the synthesis of methanol, offering distinct advantages in efficiency and precision. This innovative method utilizes microwaves to energize a gas, creating a high-temperature plasma environment conducive to the synthesis of methanol from a variety of feedstocks, including carbon dioxide and hydrogen. The controlled conditions within the plasma chamber enable rapid and selective reactions, enhancing the overall efficiency of methanol synthesis. The high temperatures and specific energy distribution achieved through microwave-generated plasma facilitate a more direct and streamlined conversion process, minimizing unwanted byproducts. This approach holds promise for sustainable methanol production, contributing to the development of cleaner and more energy-efficient chemical synthesis methods in the ongoing quest for environmentally friendly technologies.

Our Management

Simon Vogt

Founder & CEO

Arian Voigt

Founder & CTO

Our Advisors

Dr. Manfred Anders

Managing Director

ZfB

Dr. Steffen Mozer

CEO

requisimus

Dr. Jan-Philipp Mai

Managing Director

JPM Silicon

Prof. Dr.-Ing. Christof Hamel

Chemical Process Engineering

OVG-University Magdeburg